Is ensuring that your business meets UK regulations just about compliance?

Or do they realise it’s for their own benefit?

What benefits, you ask? For starters, safety, reputation, energy cost savings, and long-term resilience.

We hope you have your shoes on, because in this guide, we’ll walk you through what business owners, facility managers, building designers, and maintenance teams need to know:

Health and safety obligations, energy targets, and environmental concerns.

Disclaimer: This is intended for informational purposes and not legal advice. This can get a little too technical, too, but don’t worry – we’ll do our best to explain everything in the clearest way possible.

Regulatory Landscape Overview

Let’s just get right down to it, then.

Health & Safety at Work and General Duties

At the core of all workplace safety is the Health and Safety at Work etc. Act 1974 (HASAWA).

This Act places general duties on employers and those in control of premises to ensure, so far as is reasonably practicable, the health, safety and welfare of employees and others.

Under that Act, more specific regulations and codes of practice have been enacted (or referenced) to deal with lighting, electrical safety, emergency systems, etc.

- The Workplace (Health, Safety and Welfare) Regulations 1992, especially Regulation 8 — This requires that every workplace has “suitable and sufficient lighting”, and (where needed) emergency lighting.

- The Management of Health and Safety at Work Regulations 1999 — This requires the completion of appropriate risk assessments, which must include an assessment of lighting adequacy.

- Building Regulations (especially Part L, dealing with energy efficiency) — This also influences how lighting should be specified in new or refurbished non-domestic buildings.

In practice, lighting design and maintenance decisions for business premises often encompass safety compliance, building standards, and energy/environmental obligations.

Workplace Lighting Requirements (Health & Safety Regs)

“Suitable and sufficient” lighting — What that really means

Stepping back to Regulation 8 of the Workplace Regulations, it mandates that lighting must be both suitable (appropriate for the tasks and environment) and sufficient (adequate in quantity).

This primarily advocates for using natural light where possible, with artificial lighting used only as a supplement.

In addition, the Health and Safety Executive (HSE)’s guidance “Lighting at Work (series code HSG38)” outlines how lighting contributes to worker wellbeing, risk control, and how to assess lighting levels in practice.

Practical Benchmarks and Illuminance Levels

While there is no single “legal lux level,” good practice and standards (such as BS EN 12464-1) and guidance (via CIBSE / SLL lighting codes) provide target levels.

- General offices: 300–500 lux on desktop surfaces.

- Corridors and changing rooms: 100 lux or less.

- General ambient areas or circulation: 50–150 lux.

- Higher-precision tasks (inspection, laboratories, technical work) may require higher levels, starting from 1000 lux to 1500 lux or more.

It is the responsibility of the one in charge to consider glare, contrast, uniformity, and visual comfort.

They should also check for flicker or excessive contrast in lighting design.

Risk Assessment and Lighting Hazards

Lighting must be part of your general risk assessment under HASAWA.

That means identifying:

- Areas with insufficient lighting that are causing slip or stumble hazards.

- Worker headache, eyestrain, or fatigue risks from poor lighting.

- Emergency lighting or backup systems in case of power failure.

- Maintenance aspects (lamp ageing, dust, degradation)

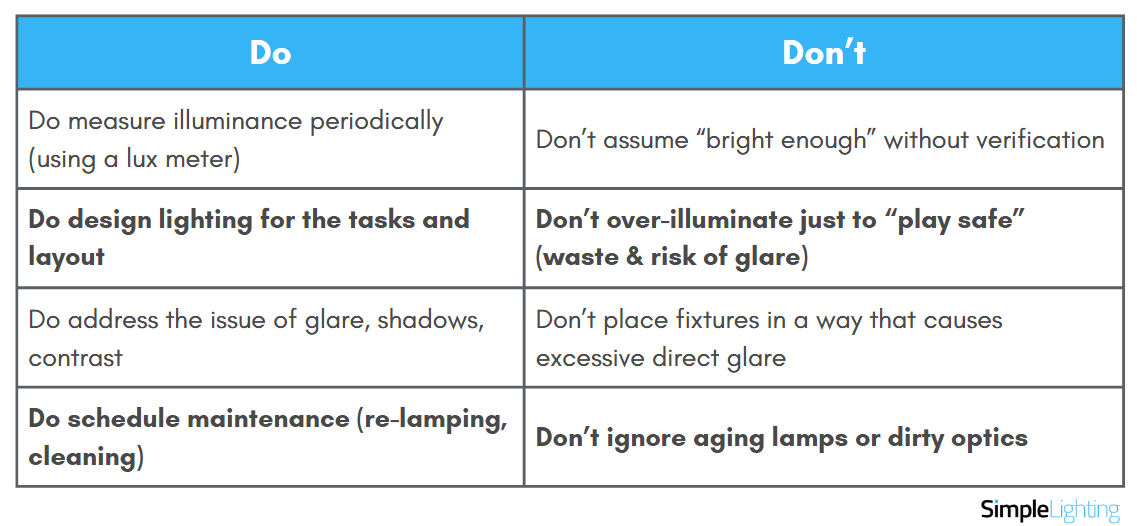

Here are some do’s and don’ts…

Emergency Lighting & Escape Routes

When normal lighting fails, whether due to a power cut, fire, or other hazards, your emergency lighting and escape route illumination come into play.

Or more accurately, they’re expected to be, as per regulations.

Business premises are often legally required to provide and maintain emergency lighting systems to ensure safe evacuation in the event of—you guessed it—an emergency.

Relevant Standards:

BS 5266-1 (Code of Practice for Emergency Lighting of Premises) is the primary UK standard on the application and practice of emergency lighting.

BS EN 1838 (Lighting Applications, Emergency Lighting) sets functional requirements for emergency escape lights. The emergency lights would provide a safe exit in the event of failure of the normal supply.

BS EN 50172 and BS 5266-8 both cover the operation, testing, and maintenance of emergency lights.

System Design, Duration & Performance

Key requirements include:

1. Emergency light fixtures should provide illumination along escape routes, exits, hallway intersections, staircases, and open emergency refuge zones.

2. A typical 3-hour operation after loss of mains supply; in some simpler cases, an hour may be acceptable if the building is evacuated immediately.

3. Light fixtures must be fire-resistant.

4. Spacing and placement: careful measurement to avoid dark zones.

Signage, Battery Backup, and Central Controls

- Emergency exit signs and pictograms must be clearly visible, usually integrated with light fixtures or as standalone sign units.

- Battery backup units must be sized appropriately. They should also be robust.

- Some systems utilise self-testing or automatic testing features, as specified in BS EN 62034 (common in modern designs).

- In large or critical premises, central battery systems or static inverters may be used.

Wiring & Electrical Safety Standards

Most lighting systems are integrated into general electrical installations.

That’s why compliance with wiring, safety, and installation standards is essential.

We’re specifically looking at BS 7671.

BS 7671 (IET Wiring Regulations)

This is, in short, the UK’s national standard for electrical installation and wiring safety, establishing the guidelines for the design, installation, and verification of electrical systems.

This specific standard ensures that these electrical wiring systems are safe for use in various applications, not just lighting.

Installation Rules & Best Practices

Not exactly breaking news, but installation without a plan or structure is not ideal, especially in the commercial setting.

Here are some key points to consider when installing your lights.

- All lighting circuits must be sized correctly, with appropriate overcurrent protection and discrimination.

- Junction boxes, connectors and enclosures must be appropriately rated and safe.

- Supplementary bonding in specific locations (e.g., wet areas) may be required.

- Earthing or equipotential bonding must be implemented correctly to meet safety standards.

- Installations must be inspected and tested upon completion (Initial verification). This includes insulation resistance tests, earth continuity tests, polarity checks, and functional tests.

Your lighting circuits should also be part of a periodic inspection to catch any defects before they become a major problem.

Energy Efficiency & Carbon Targets

The UK government and several regulatory bodies are imposing increasing pressure on businesses to reduce energy consumption and carbon emissions.

The Building Regulations Part L (now with Volume 2 – Buildings other than dwellings) has introduced higher performance targets, including a 27% reduction in carbon dioxide emissions for non-domestic buildings.

In September 2021, the UK had already banned the use of halogen lamps, and T8 fluorescents are being gradually phased out to promote the adoption of LED technology.

Controls, Daylighting & Smart Strategies

- Incorporate presence (occupancy) sensors, daylight harvesting, dimming, and zoning to reduce power.

- Use timers, task-level switching, adaptive controls, and integration with building management systems (BMS).

- Utilise high-efficacy LED fixtures that offer good lumen maintenance and high control flexibility.

- Monitor energy use via sub-metering and analytics to spot waste or inefficiencies.

Light Pollution & Environmental Considerations

Modern regulators and local planning authorities are increasingly aware of the ecological and community impacts of light pollution.

It’s not just something you learn about in schools anymore.

It’s real, and it is a problem.

Ever Heard of ULOR?

The Upward Light Output Ratio (ULOR) indicates the degree of light emission above the lamp holder.

A favourable ULOR is found in lamps that direct the light where it is needed: on the road and pavement.

With sustainability and energy efficiency becoming a priority in public space designs, the ULOR factor takes particular importance.

The goal of road, street, and park lighting has evolved not only to give adequate lighting, but also to minimise its negative effect on the environment.

Some Design Considerations

- Avoid upward light emissions.

- Use fully shielded or cutoff fixtures, downward-directed optics, and control glare.

- Choose warm colour temperatures (2700K–3000K) where ecological sensitivity is a concern.

- Use dimming or “curfews” (like switching off or dimming external lighting after midnight) where permissible.

- Be conscious of the impact on wildlife and sensitive neighbours.

Record Keeping, Testing & Maintenance Obligations

A good business documents everything.

Yes, even your lighting activities.

Good documentation and maintenance are as important as compliance with installation standards.

Keeping records allows you to demonstrate due diligence in audits or in the event of an incident. (Hopefully not the latter, but one has to be prepared.)

What To Record:

- Lighting design specifications, layout drawings, and photometric data

- Installation certificates, test reports (initial verification)

- Electrical inspection reports or Electrical Installation Condition Report (EICR)

- Emergency lighting logbook (monthly, full tests, repairs)

- Maintenance schedules, lamp holder replacements, driver replacements

- Change control/upgrade records (if replacing luminaires or adding controls)

- Risk assessments and any lighting-related hazard logs

Maintaining a robust log and clear records is essential for insurance claims, safety inspections, audits, and demonstrating compliance to regulators or enforcement bodies.

Routine Testing and Maintenance

Keeping your lights in prime condition is not only good for compliance but also crucial for the safety and well-being of your staff and others.

Things to check regularly:

Light level checks — Periodically measure illuminance across work surfaces and circulation zones to verify compliance or detect deterioration.

Also, LED lights may last a long time, but they tend to dim towards the end of their lifespan.

Emergency lighting tests — Per monthly and annual requirements.

Cleaning and re-lamping — Dust build-up and ageing degrade light output. Clean regularly, polish lenses, and replace lamps as needed.

Control system calibration — Ensure sensors, dimmers, and timers are functioning and correctly tuned.

Fault monitoring and response — Address failures quickly, log repairs, and inspect any cascading faults.

Common Compliance Mistakes & How to Avoid Them

Hey, no one is perfect. Even experienced facility managers make missteps.

Below is a summary of frequent pitfalls and how to sidestep them.

1. “Install and forget” mentality

The long lifespan of LEDs does not mean you can neglect them. Over time, output degrades, sensors drift, and dirty optics accumulate.

How to Avoid: Schedule periodic reviews, illuminance rechecks, and reprogramming controls to prevent issues.

2. Inadequate emergency system coverage or testing

Emergency lighting may be installed but not tested, incorrectly spaced, or inappropriately rated (such as only having one hour of illumination instead of three hours).

How to Avoid: Follow BS 5266, performing monthly and annual tests, validating spacing via photometrics, and correcting gaps.

3. Poor documentation / missing logs

Without proper logs, you can’t prove you’ve done your due diligence. Simple.

How to Avoid: Set up a clearly accessible logbook (which can be digital), recording all tests, repairs, certificates, changes, and other relevant information.

4. Oversizing, overlighting, or energy waste

Some businesses use more lighting than needed (to “play safe”) or leave lights at full brightness all the time.

How to Avoid: Use controls, zoning, and daylighting.

5. Ignoring local planning / environmental constraints

Especially for external lighting, failure to consider glare, light trespass (unwanted light from a neighbour), or local planning constraints can result in enforcement action.

How to Avoid: Use shielded and downward optics, control timing, and document compliance.

6. Using non-compliant or substandard gear

Cheap or poorly specified light fixtures, drivers, or control gear may not meet safety or efficiency standards.

How to Avoid: Procure products from reputable suppliers, such as Simple Lighting, to ensure that you’re using high-quality lights that meet standards.

7. Lack of integration among systems

Sometimes, lighting, fire, BMS, and security systems are designed in isolation, causing overlap and conflict.

How to Avoid: Have a holistic design review, coordination meetings, and ensure agreements among interfaces (such as BMS integrations).

Conclusion and Next Steps

Lighting compliance extends beyond simply checking boxes.

It governs everything from safety and productivity to energy efficiency and environmental impact.

As a business, it is your responsibility to ensure that all of these are met.

What you should do now:

1. Audit your current lighting systems (task vs ambient, control, maintenance).

2. Review your emergency lighting systems: check coverage, test schedule, and logbooks.

3. Ensure that electrical installations are properly documented and regularly inspected.

4. Plan upgrades using high-efficiency LED fixtures, controls, and energy-smart strategies.

5. Implement a maintenance and record system that tracks all lighting changes, failures, tests, and repairs.

6. Consult local planning and environmental guidelines for external lighting schemes.

Simple Lighting offers a wide range of high-quality lighting products that are carefully designed to comply with all UK standards.

Visit our website now to take the first step in creating a regulation-compliant lighting system.