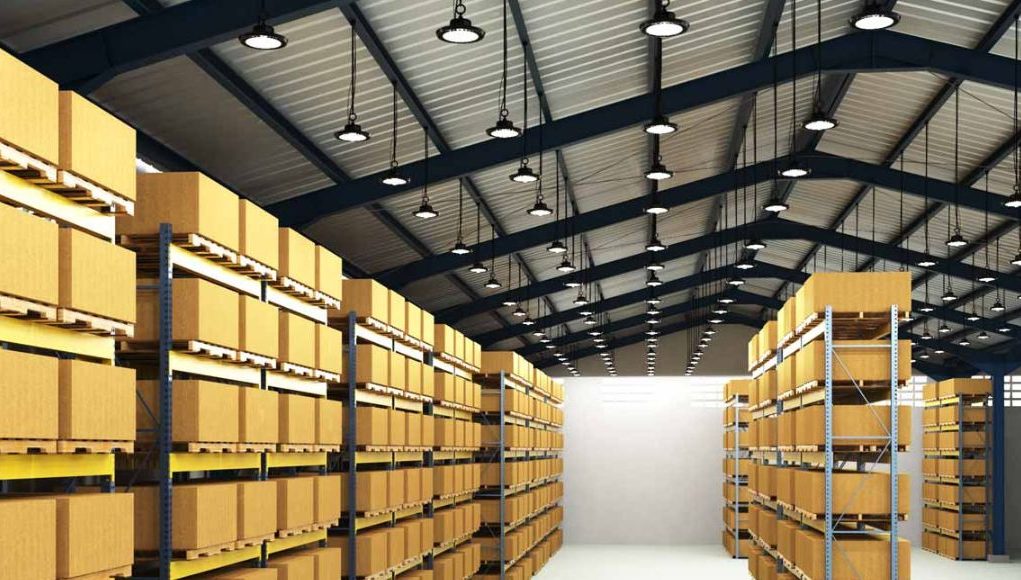

This might go without saying, but lighting a warehouse or any industrial facility isn’t the same as lighting an office.

Mounting heights alone can soar to eight, 12, or even 20 metres. Not to mention that the sheer square footage of the area you’re going to light is massive. Using the wrong lights can result in poor visibility, wasted energy, and safety risks for staff.

And yet you want your warehouse lights to positively impact productivity, compliance, costs, and even employee morale. The stakes are high when it comes to industrial lighting.

That’s why in this guide, we’ll explore proven strategies for lighting high-ceiling industrial spaces. We’ll cover everything, from fixture choice, layouts, controls, safety, and maintenance.

We hope you’re ready to create a well-lit, efficient, and future-ready facility, because we’re diving in.

Challenges Unique to High Ceilings & Big Spaces

Let’s address the biggest elephant in the room: the space (both vertical and horizontal).

1. Light Distribution

In spaces that need good visibility, having lights with the right beam angles is crucial for properly spreading illumination across racks, workstations, and aisles. Poor light distribution leads to glaring hot spots directly under the fittings and dark shadows in between.

2. Mounting Heights

We all know that the further the light source is, the less effective it becomes. So, the higher the ceiling, the more lumens you need per fixture. The lights that work well in a retail shop or a car park won’t suffice when the ceiling height is 12 metres.

Brightness falls off quickly over distance, after all. That’s why industrial high bay lights are specifically engineered to punch light downwards while maintaining uniformity.

3. Maintenance Access

Changing a bulb in an office is easy. Now try swapping one at 14 metres up in a busy warehouse. We’re talking about using scaffolding or cherry pickers.

That’s why fixtures must be chosen for longevity and reliability to reduce the need for disruptive maintenance.

4. Harsh Environments

Dust, vibrations, temperature fluctuations, and even humidity can all shorten the lifespan of fixtures. In warehouses and factories, lighting must be robust, sealed, and resilient.

Bottom line: Office and commercial lights are out of the equation when talking about industrial applications. High ceilings and vast spaces demand purpose-built lighting solutions that strike a balance between brightness, distribution, and durability.

Choosing High Bay & Low Bay Fixtures

Armed with the knowledge of all the challenges mentioned above, the question then arises: Should you install high-bay or low-bay fixtures?

What’s the difference?

High Bay Lighting

- Designed for mounting heights of 6 metres and above (typical for warehouses, sports arenas, hangars).

- Uses narrower beam angles (60°–90°) to push light down over long distances. Smaller beam angles concentrate the light.

- Ideal for illuminating large open areas or tall racking systems.

Low Bay Lighting

- Best for mounting heights between 4 to 6 metres. The power is typically smaller, hence the need for a lower height.

- Uses wider beam angles (over 120°) to spread light across smaller, lower spaces.

- Common in workshops, smaller production floors, or storage areas with lower ceilings.

Beam Angle Considerations

Think of the beam angle like the opening of a spray nozzle. The smaller the opening, the stronger the water jet is, and the further the water sprays. The wider the hole, the bigger the water flow, but the shorter the distance travelled.

Warning: Too wide, and light gets lost before it hits the floor. Too narrow, and you’ll end up with bright pools and shadows in between.

You need to choose the right beam angle to ensure:

- Uniform coverage in open floor areas.

- Focused illumination in racking aisles where vertical surfaces matter.

Layout & Uniformity: Avoid Dark Spots

Planning and layout are important aspects of lighting.

Even the most powerful light fitting can fail if the layout isn’t designed for uniformity. Poor layouts in industrial settings create dangerous dark zones, inconsistent lighting across workstations, and complaints from staff.

The Grid Approach

A lighting grid ensures that light outputs overlap slightly, eliminating shadows. For open spaces, use square or rectangular layouts depending on room proportions.

Spacing Ratios

There’s something called the space-to-height ratio (SHR) when it comes to lighting. The common SHR for industrial illumination is 1:1 to 1:1.5.

For example, if your lights are mounted at 10m, fixtures should generally be spaced 1–1.5 times that height apart (10–15m).

- Too wide, and you’ll see gaps.

- Too close, and you waste energy.

Remember: A well-planned lighting layout eliminates shadows, enhances productivity, and reduces accidents.

Controls, Sensors & Zoning in Warehouses

Lighting controls are no longer optional. They’re a necessity. And they’re a business-critical tool for cutting costs and improving flexibility.

Occupancy Sensors

Warehouses often have areas with sporadic use. Motion or presence sensors ensure that lights only operate when someone is present in that zone, eliminating the need to fumble for the light switch. It’s also especially helpful when carrying heavy loads.

Aisles, loading bays, and storage corners are ideal candidates for lights equipped with motion sensors.

Daylight Harvesting

Facilities with skylights or windows can benefit from daylight sensors that automatically dim artificial lighting when natural light is sufficient.

Cut costs without sacrificing good lighting.

Zoning & Task Lighting

Bright lights are great for maintaining good visibility. But not every corner of a warehouse requires the same level of brightness. That’s why it’s important you create “zones.”

With zoning, you can:

- Increase brightness over packing and inspection stations.

- Reduce lighting in areas that are unused or seldom visited.

- Keep racking aisles at standard lux levels.

Essentially, it’s ensuring that you have the proper amount of light required for each zone at all times.

Centralised Controls

Modern LED systems can be integrated into building management systems (BMS) or building automation systems (BAS). It’s basically a computerised control system that automates and centralises scheduling, monitoring, and reporting of everything inside the building.

Why it’s important: Smart controls can reduce warehouse lighting energy use, which can dramatically improve ROI. Now who wouldn’t want that?

Emergency & Safety Lighting in Industrial Spaces

Emergency lighting in warehouses is not just about compliance with standards. In settings with large machinery, it can be what stands between life and mortality.

What we mean to say is: light is a lifesaver.

Also, on a less morbid note, high ceilings, complex layouts, and long travel distances make warehouses particularly challenging during power cuts or emergencies.

Staff must be able to evacuate safely, and emergency crews must navigate without delay.

Here are some key requirements:

- Emergency exit routes: Clearly illuminated with compliant exit signage.

- High-risk task lighting: Critical areas like machinery zones may need back-up lighting to allow safe shutdown.

Testing & Reliability

Regularly testing emergency lights is essential to ensure that they work as intended in times when they’re needed.

But monthly tests can be time and resource-consuming. Some LED emergency fittings with built-in self-test functions reduce labour and ensure compliance is never overlooked.

A well-designed emergency lighting ensures safety, compliance, and peace of mind.

Energy Efficiency & LED Retrofit

Do you know what the biggest driver for lighting upgrades is? It’s not love for nature. It’s energy savings. And the common (and most beneficial) lighting upgrade is LED light installations.

Here’s why:

- Uses at least 75% less energy compared to traditional light systems

- Instant-on (no warm-up delays common in old discharge lamps).

- Consistent light quality with no flicker.

- Longer lifespan (typically 20,000 to 50,000 hours), reducing maintenance and replacement costs.

- Smart controls and automation add more to the energy saved.

Retrofit vs New Install

Retrofit LED lamps can fit existing fixtures, lowering the upfront cost, but sometimes compromising optics.

New LED high bays are purpose-built for efficiency and optics, offering higher performance and often better long-term ROI.

In short, LED is no longer a “nice to have” lighting choice. It’s the only sensible option for industrial lighting.

Maintenance, Cleaning & Access

Maintaining warehouse/industrial lights is no easy feat. We’ve already established that a few sections ago. That’s why maintenance planning is critical for these settings.

Longer Lifespan Fixtures

Most industrial-grade LEDs have robust housings and long warranties. Every extra year of reliable operation reduces downtime and access costs.

Easy Access Designs

The faster you can get to the fitting, the faster maintenance runs can go. Consider fixtures with:

- Quick-release latches for faster servicing.

- Modular drivers that can be replaced without needing to lower the entire fixture.

Cleaning Challenges

Dust and debris can reduce output over time. That’s why having lights with high ingress protection (IP) ratings is necessary to prevent build-up.

Schedule periodic cleaning, particularly in food, pharmaceutical, or dusty manufacturing environments, to maintain consistent lux levels.

Also consider lights with easy-to-clean exteriors rather than ones with ornate designs (those are dust magnets).

Planned Maintenance vs Reactive

Waiting until a lamp fails can lead to uneven lighting and safety issues. Proactive maintenance schedules ensure consistency and reduce emergency call-outs.

Final Word

Lighting is one of the largest energy and safety factors in any warehouse or industrial application. Getting it wrong risks compromising the productivity, energy efficiency, and safety of the facility.

Getting your lighting right means:

- Safer workplaces with fewer accidents.

- Higher productivity with clear visibility in every zone.

- Lower costs through energy efficiency and reduced maintenance.

Whether you’re upgrading an existing warehouse or planning a new build, the strategies above will help you design a system that delivers clarity, compliance, and cost savings.

The good news is that Simple Lighting has a long track record of supplying high bay LEDs, controls, and emergency lighting solutions to warehouses and industrial facilities across the UK.

It’s safe to say that we understand the challenges of high ceilings, complex layouts, and the need for ROI-driven solutions.

Check our website now to take the first step to lighting your warehouse right.